Winter Driving is more than having a 4 wheeled drive or experience in the frozen north. It is about preparedness, common sense, and looking out for other drivers. I have seen all manner of accidents caused by winter driving conditions, and know the damage vehicles can do. When driving in wintry weather: slow down, stretch […]

Month: December 2010

How to Prepare for Winter Weather

Preparing for winter weather involves more than just buying salt and hot chocolate. Stock up on non-perishables, like canned goods, and make sure you have adequate medical supplies and prescriptions. I have worked winter storms that have wrecked havoc on the unprepared – cold weather can kill – and it can cause accidents that kill […]

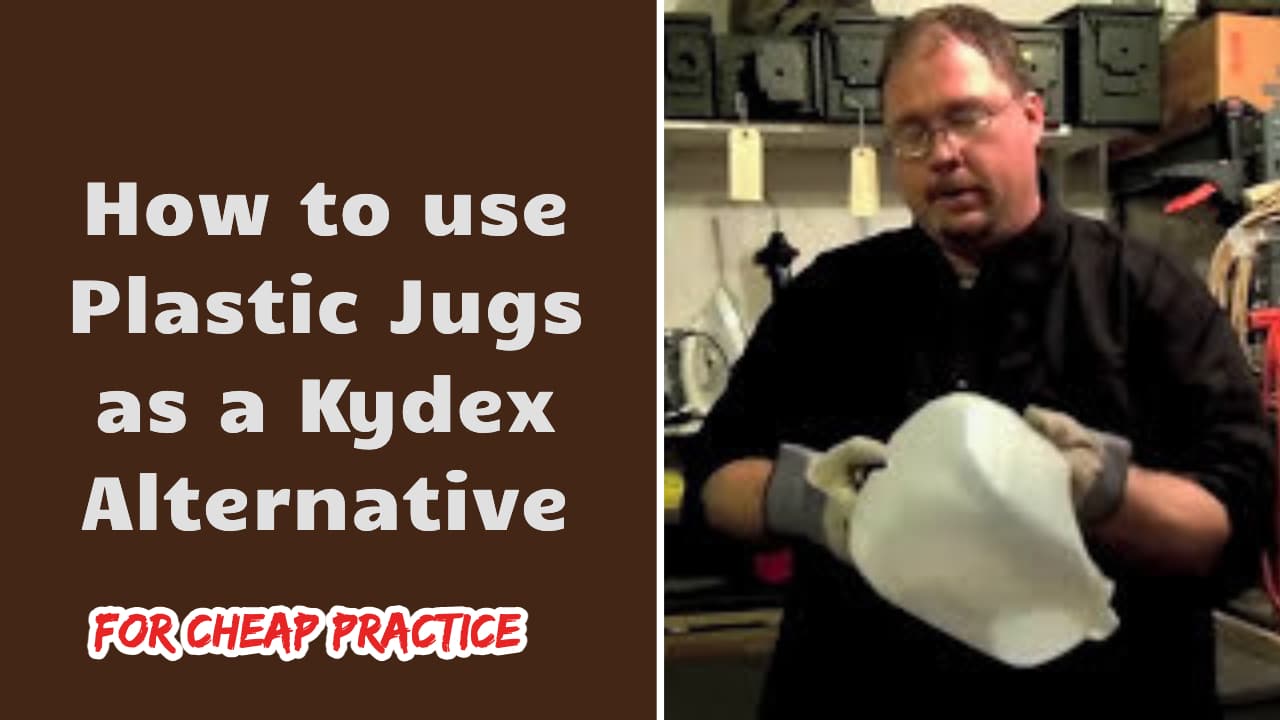

How to Build a Homemade Kydex Press

Being a carry permit holder I have a thing for gun holsters, being a big guy, I spend a lot of time baking sure that my holsters are comfortable and work well with the clothing I wear. Something I have noticed “gun guys” is that we all have a box of old holsters. The […]