This is one of those posts in which I expect an expert to rip me to shreds over my technique. I would deserve it as this is a precision machining technique. However, I butcher it with hand tools and a total lack of precision. I am going to show you a rough approximation of […]

Month: July 2015

How to Retread a Lawnmower Tire

I saw this on a youtube video a few years ago and kept it in mind for the day I needed it. Basically both the originator of this idea and I both used an old bike tire to cheaply retread a lawnmower tire. This takes a little work, but it is much cheaper than […]

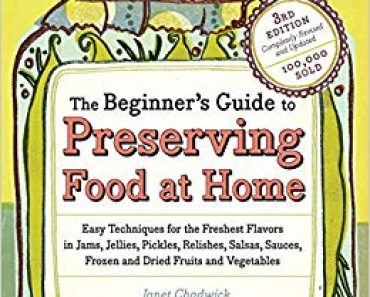

The Beginners Guide to Preserving Food at Home

A wonderful thing is happening in home kitchens. People are rediscovering the joys of locally produced foods and reducing the amount of the grocery budget that’s spent on packaged items, out-of-season produce, and heavily processed foods. But fresh, seasonal fruits and vegetables don’t stay fresh and delicious forever – they must be eaten now . […]

Tiny House Delivery

EDIT: It took so long to post this that the guy that was going to pay his rent by working on the land to “heal the land” actually caused more problems than he solved – meaning dumping his composting toilet (5 gallon bucket) out on the grass, rutting over the septic lines, and basically refusing […]

Basic Machines and How the Work

Only elementary math skills are needed to follow this instructive manual. Basic Machines and How the Work covers many familiar machines and their components, including levers, block and tackle, and the inclined plane and wedge, in addition to hydrostatic and hydraulic machines, internal combustion engines, trains, and more. 204 black-and-white illustrations. This book is a […]