This is an experiment in using spray foam alone to insulate a conex box.

This particular spray foam in a conex box idea did not work. The problem was the box developed condensation inside which caused the spray foam to fall off.

If I had supported the spray foam by adding a sheet of foam or other backer the spray foam in a conex box would have stayed up.

Additionally, I think that if I would have done it in a warmer time, or roughed the pain to allow better adhesion it would have worked better.

The next plan is probably better (and cheaper) as I will use my foam cutter to slice foam board into strips to glue into the conex side corrugation and then I will use spray foam to seal the sheets into a single mass.

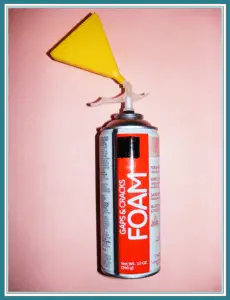

In reality, I bought a foam nozzle that spread the foam into a wide stream and wanted to try it out. I did not really think this would work, and kinda did not want it to.

In reality, I bought a foam nozzle that spread the foam into a wide stream and wanted to try it out. I did not really think this would work, and kinda did not want it to.

This is because a can of foam is around $5.00 and it took a can to do about one and a half strips.

Which would mean it would be cheaper to pay a commercial spray foam installer to come and puts pray foam in a conex box