Compared to other natural disasters like hurricanes and fires, earthquakes strike without warning anywhere in the world. There’s no telling when they’ll happen and most of the time, they bring extensive damage. During an earthquake, your own home itself can become a danger to you and your family. How can you prepare your own home […]

Category: How To (How I Did)

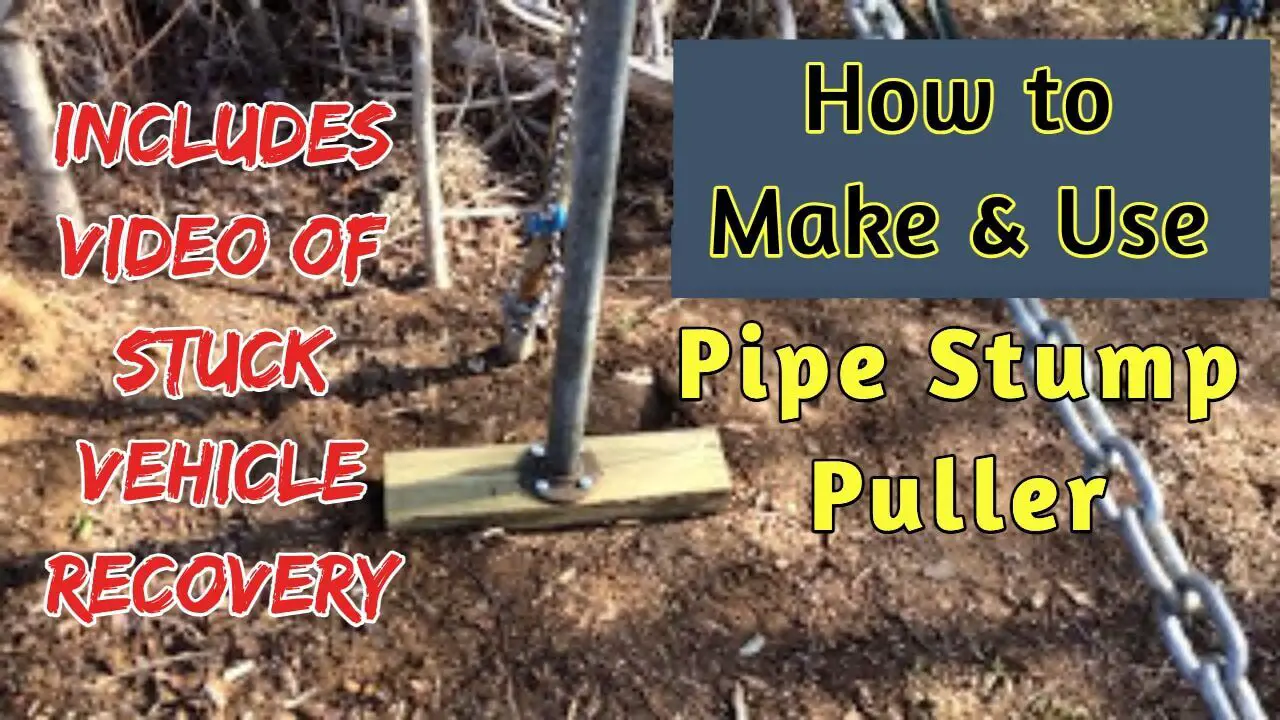

You could call this a How To – but people often tell me I did it wrong – now to be fair you can’t really tell me I can’t do it that way, when the video shows I actually DID do it that way – so to cool down the hateraide – lets just call this HOW I DID

Mobile Home Demolition

The Mobile Home Demolition was not as hard as I thought it would be, of course it was messy, tiring, and seemingly never ending. Once we figured out a system the process went much faster. First we used the backhoe to smash down the walls, and then used the truck and a chain to pull […]

Tips For Non-Carpenters on How to Build Your Own

I am not a carpenter by profession. However, I have a strong desire for the carpentry work. I have a passion for the woodwork. You cannot deny the fact that carpentry is a significant job and almost all the home needs it for some or other reason. Actually, it beautifies your home interior and brings […]

How to Build a Paracord Carabineer Spool

This Paracord Carabineer Spool project that is very useful for outdoors-men of all types. It is just an way of carrying cordage in a way that is easily accessible. If you can get a section of PVC pipe around a carabiner (more on this latter) and zigzag spool 550 or tethering cord around it, you […]